While epoxy adhesives are often used to mechanically secure wires or small components on a printed circuit board, they can also introduce unwanted side effects if applied directly over solder joints or delicate SMD pads. This is mainly due to internal mechanical stress that develops during the curing process. This is something I learned the hard way while working on my own radio project.

In my case, I was not aware that such internal stresses could occur, as the epoxy was applied gently and left to cure without any movement, vibration, or heat.

What Happens During Curing

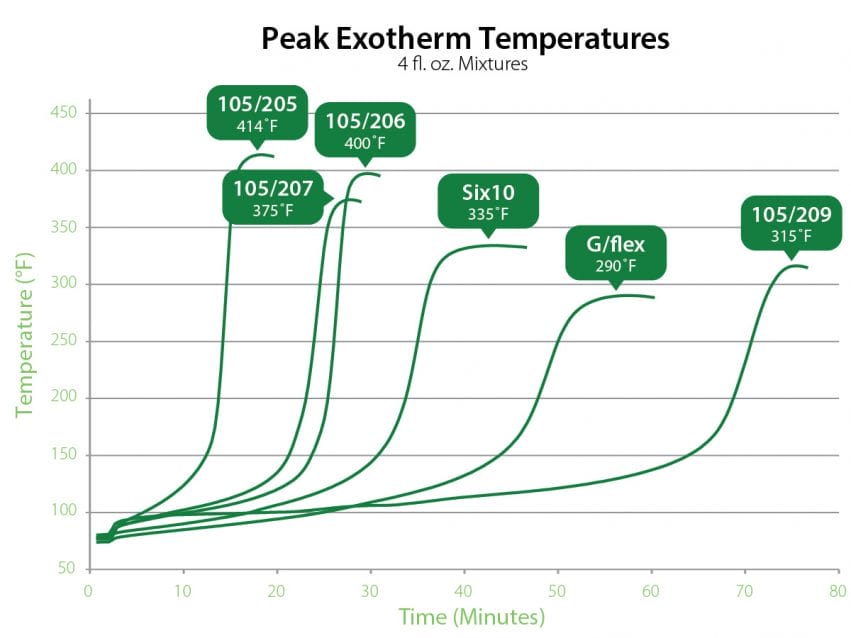

Most 5-minute epoxies generate a small amount of exothermic heat as they cure. Even though this heat is relatively low, it can still locally affect freshly soldered joints. Nearby components may also experience mild thermal stress. In addition, epoxy slightly contracts as it hardens — this cure shrinkage can create tensile stress between the adhesive, the solder joints, and the copper pads.

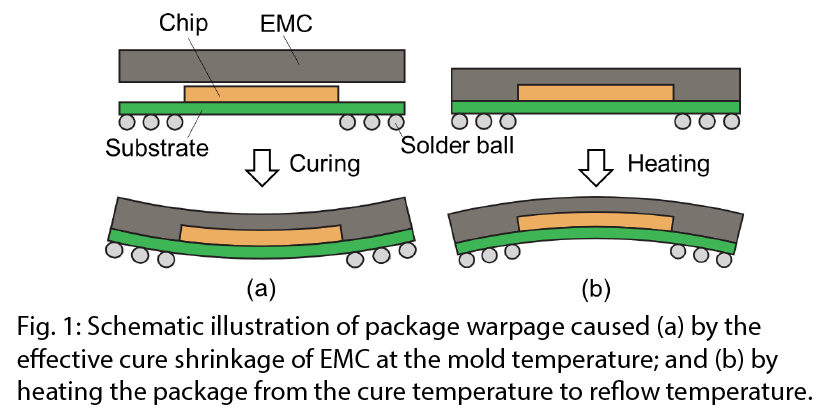

Figure X: Schematic illustration of mechanical stress and warpage caused by epoxy curing and thermal expansion mismatch. During curing (a), the epoxy molding compound (EMC) shrinks slightly, pulling on the substrate and creating tensile stress. When reheated (b), the difference in the coefficient of thermal expansion (CTE) between the epoxy, copper, and substrate leads to further bending and residual strain.

Source: Han et al., “Warpage of Electronic Packages,” CALCE / University of Maryland (adapted from original).

Because the coefficient of thermal expansion (CTE) of epoxy differs from that of copper and FR-4 laminate, residual strain can form as the material cools down. On older PCBs, where the bond between the copper pads and substrate may already be weakened, these internal stresses can be enough to lift pads or fracture fragile solder joints, even without external heat or vibration.

It is also possible that the stress developed gradually as the epoxy continued to cure and shrink over time, which could explain why the connection problems appeared only during later testing.

Figure X: Typical exothermic heat profile of mixed epoxy resin during curing. Even small amounts of fast-curing epoxy can reach elevated temperatures due to the exothermic chemical reaction, potentially affecting nearby solder joints or PCB materials.

Source: Epoxyworks – “Controlling Exotherm” (Gougeon Brothers / West System).

Possible Effects

These combined factors can lead to:

- Lifted or partially detached copper pads

- Cracked or intermittent solder joints

- Local delamination of the PCB surface

- Unstable electrical connections that appear only after full curing

In my case, the issue showed up as intermittent signal loss on the receiver, which at first seemed completely random. Only after inspecting the board more closely did I notice that several pads near C1473 were slightly lifted.

Even though such failures are rare, they can occur when epoxy is applied in thick layers, covers active solder joints, or when the PCB is aged and mechanically fragile.

How to Prevent Such Damage

After this experience, I started looking for possible explanations and found several discussions and technical notes describing similar situations.

According to these sources, some types of epoxy can produce local stress during curing, especially if applied in thicker layers or over soldered joints. Flexible or low-shrink formulations designed for electronics may reduce this risk, but at the time I didn’t know such differences existed.

For any future work, I’m considering using other materials such as hot-melt glue or a neutral-cure silicone that is rated for electronics, as these are more flexible and less likely to create mechanical stress during curing.

These findings helped me better understand what likely happened in my case and why the problem appeared only after the epoxy had fully cured.

When it comes to silicones, I’ve learned that not all are suitable for use around PCBs.

The acid-cure (acetoxy) types, which release acetic acid during curing, can corrode copper and other metals and should be avoided.

In contrast, neutral-cure silicones — often labeled as RTV-neutral, RTV-silicone, or electronics-grade — are designed for sensitive components, producing no corrosive vapors and offering good flexibility even after full curing.

These are commonly used for strain relief, vibration damping, and general protection of soldered joints.

References and Further Reading

The following sources helped me better understand the possible causes and effects of using epoxy in PCB assemblies:

- StackExchange – Negative consequences using epoxy glue to fix lifted SMD trace/pad ↗

- AllAboutCircuits Forum – PCB Epoxy Best Choices ↗

- PCBX.com – Lifted Pad and Issues on Printed Circuit Boards ↗

- CircuitRework.com – Surface Mount Pad Repair (Epoxy Method) ↗

- Wikipedia – Pad Cratering ↗

- Epoxyworks – Controlling Exotherm: Understanding Heat Build-Up During Curing ↗

- CALCE / University of Maryland – Warpage of Electronic Packages (Han et al.) ↗

Hopefully, sharing this experience will help others avoid similar issues and choose safer materials when working near sensitive SMD components.